According to precision and adaptability, laser engraving machines find extensive application in the manufacturing sector. The efficiency of these machines has been increased through the integration of computer technology. This article also describes how laser gravure cnc engraving machines are more effective when computer-operated.

Precision and Accuracy

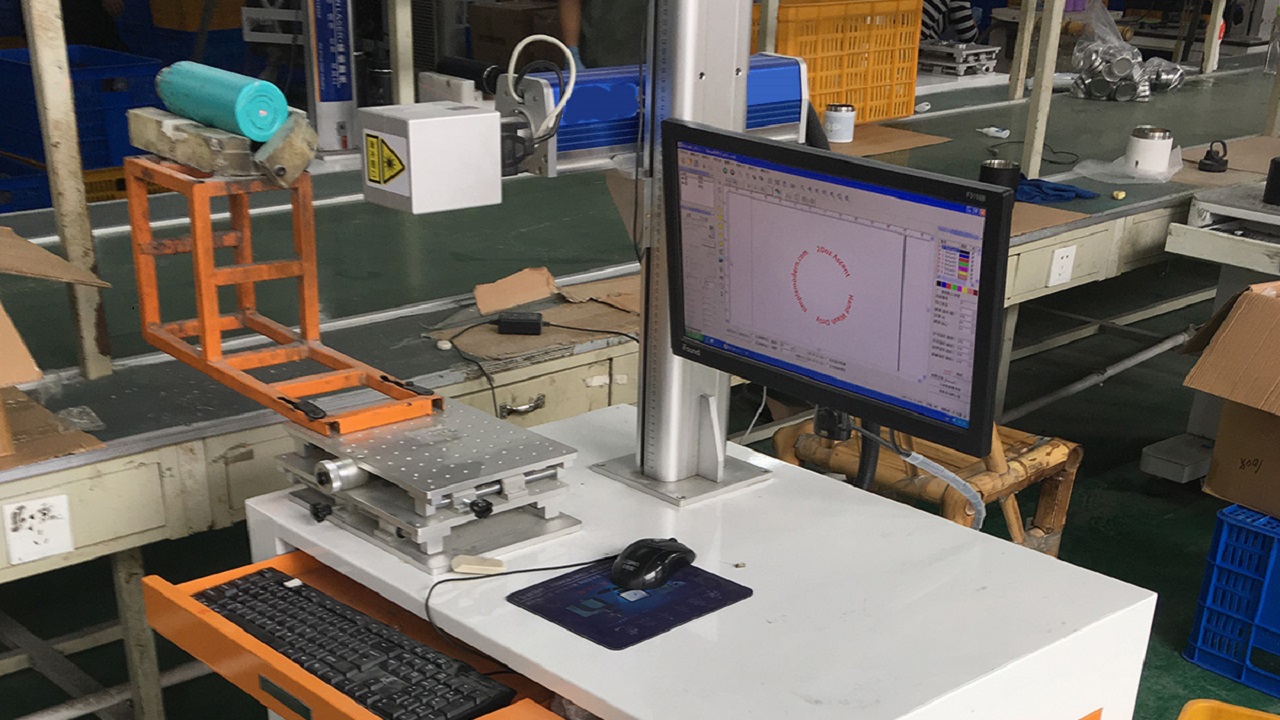

One advantage is that we get more precise engraving that results from combining computers and laser engraving equipment. Computers are used to control the laser's power and speed, enabling the creation of complex designs that are impossible to accomplish by hand.

Design Software Integration

Software such as Adobe Illustrator allows users to create complex patterns and artworks that can be easily transferred to the laser engraving machine. This assists in ensuring that every line, curve, and even the details are well captured on the material in question.

High-Resolution Output

Laser engraving machines are computer-controlled, the output is very sharp and detailed, and therefore it is possible to engrave complex designs and letters.

Enhanced Efficiency and Speed

Computers enhance the rate of work and the speed at which laser engraving is done as compared to traditional methods. When the design is fed into the engraving machine, it can then be operated by the computer and can be run on its own.

Batch Processing

This is because computers enable the engraving of many items at once. This is particularly useful for special orders and large-scale production where all the products that are manufactured will be of the same standard and the time taken to produce them will be significantly less.

Flexibility and Customization

Another benefit of laser engraving machines is the integration of computers because of the flexibility that comes with it. It allows a high degree of freedom and adaptability regarding the application and the material.

Versatile Design Capabilities

Computer software can accept different design forms and designs. Because computerized laser cutting is possible, the laser's parameters can be changed based on the material being utilized, such as leather, acrylic, metal, or wood. This adaptability guarantees the optimal result based on the substrate being used.

Minimizing Errors and Quality Control

The use of computers in laser engraving machines reduces the possibility of errors and improves the quality of the products. Laser control by computers minimizes the chances of deviations and imperfections, and therefore the engravings are much better than other techniques.

Design Verification

With the engraving process starting, the user can make a preview of the design using the computer software utilized in the procedure. This helps guarantee that any mistakes or even design defects are found and fixed before the process starts.

Data Management and Tracking

Laser engraving machines are defined by their ability to incorporate computers that enhance the data management and tracking of the general performance of the equipment.

Design Storage

It is possible to save and categorize different design files in computer systems. This makes it easy to recall and utilize designs, thus minimizing the time spent in redesigning the same from scratch.

Order Tracking

In the case of businesses, computers can be used in ordering tracking, customer information, and production schedules.

Conclusion

The combination of laser engraving machines with computer technology has improved the efficiency and prospects of the engraving field. This integration has revolutionized customization and manufacturing by enhancing accuracy, speed, flexibility, and quality control. This is why the application of laser engraving machines and computers will only increase in the future of engraving.